Basic

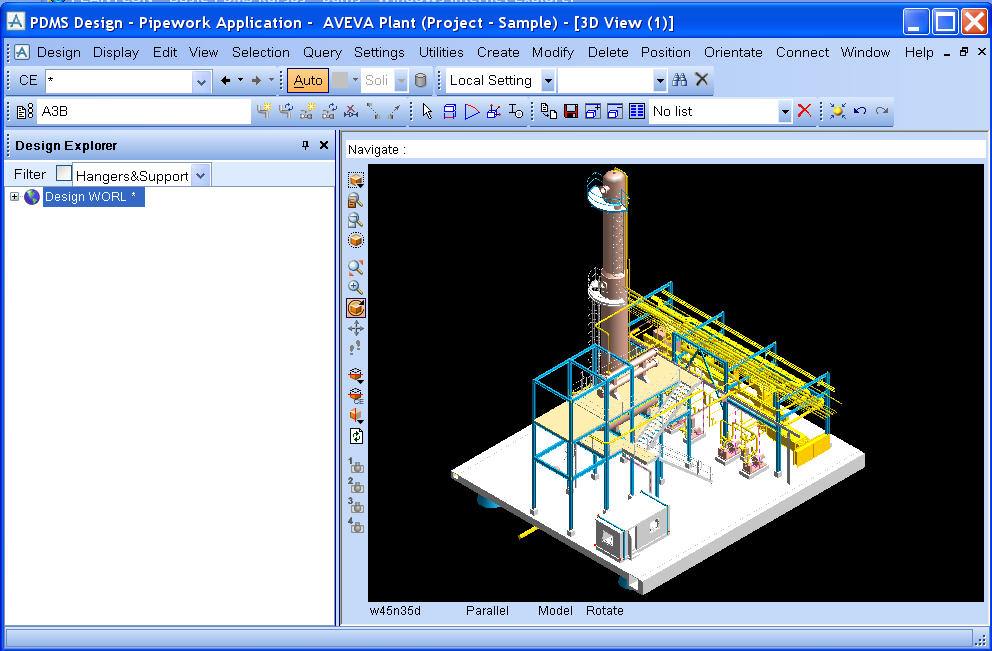

PDMS Design

Draft og

Isodraft

What it's about

A basic practical introduction to the use of PDMS for equipment and piping design, steelwork design, making Reports, Drawings og Isometrics

Who it's for

Other users who need a solid grounding in PDMS before taking on responsibility for other aspects of PDMS and its family of related products.

Duration

10 days (2 weeks)

This course is really a combination of a piping & equipment course, a steel course, a drawing production course and the Isometric course

- 1,5 days Equipment Design

- 3 days Pipe Design

- 2,5 days Steel Design

- 2 days Drawing Production

- 0,5 day Isometric

- 0,5 day presentation of other modules e.g. Review

Topics covered

Gives a solid grounding in PDMS:

Equipment and Piping Design- The principles of a database within the PDMS design hierarchy.

- The way catalogues, specifications and design data link together.

- Basic use of a workstation, mouse, keyboard (only if required).

- Using the graphical user interface to select options from the menus.

- Building up a model from real engineering drawings by creating, orientating and positioning equipment using any of the mixture of design primitives.

- This will involve the following practical stages:

- Routing simple pipes (basically orthogonal routes) and using the Query facility.

- Checking the modelled pipework for any data consistency errors, interpreting any errors found and carrying out the necessary modifications.

- Producing reports on any elements in the design data, and illustrating the scope for variation in selection and report format.

- Checking the model for any interference (Clash Detection), producing error reports and interpreting any errors found and making the necessary modifications.

- Understanding the differences between on-line and command line Clash Detection, and how and when to use each type.

- Regular steelwork, columns and beams, nodes, joints and fittings.

- Platforms: Access stairs & Ladders

- Panels & Plates

- How the hierarchy in the Drawing Production Module (DRAFT) is constructed.

- Using the graphical user interface to select required options from the on-screen and pull down menus.

- How to use the drawing production tools

- How to produce completed drawings and plotfiles, using the Drawing Production tools.

- Creating new drawings containing single or multiple views.

- Seeing the effects of design data changes on the drawings.

- How to insert dimensions and annotations on any view using 'Intelligent text' to extract data from the design database.

- Creating simple detail views of areas of interest and scrap views.

- Creating a section to show particular view information.

- Using the extensive 2D drawing facilities.

- The use of local rule changes.

- The different forms of piping isometrics and the variations in their format.

- Where the reference data is stored within PDMS and the format in which it is extracted by the isometric system.

- Using the graphical user interface to select required options from the on-screen and pull down menus.

- Producing isometric drawings for the drawing frame and title block pipe picture material list, using any of the available options.

- Producing bespoke isometrics to suit company requirements.

- How the isometric system would be used in a production environment and the controls available for revising or reissuing drawings.

- Controlling drawing content for fabrication and managing weld and material traceability.

When

Ask PLANTCON A/S, telephone +45 2751 0174 or

by E-mail: kek@plantcon.dk

Where

On PLANTCON A/S in our trainingcenter - or on customers locations.